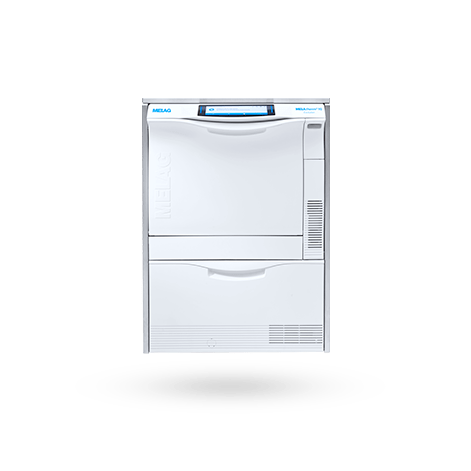

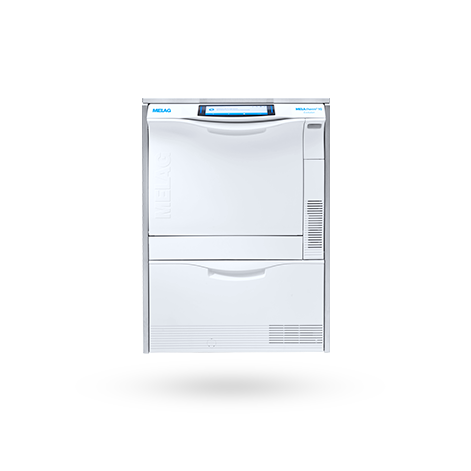

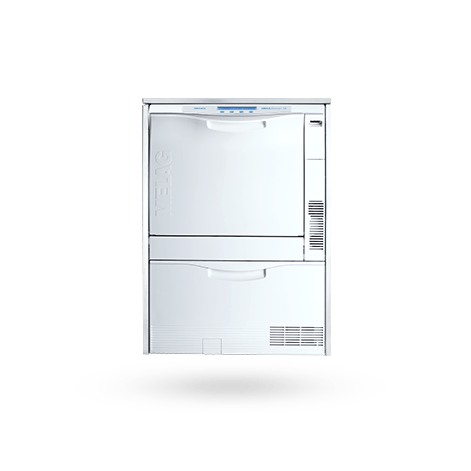

The use of a thermal disinfector offers numerous advantages that make everyday work in the practice considerably easier and at the same time increase safety.

1. time saving and efficiency

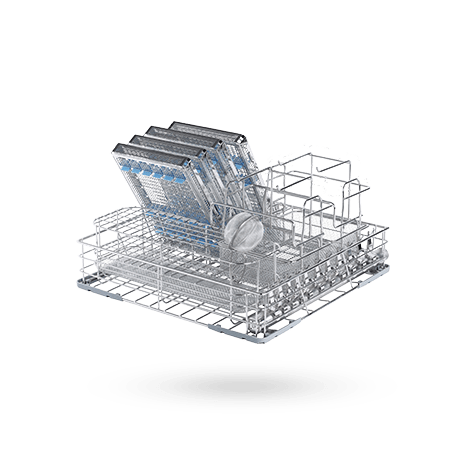

The washer-disinfector enables fast and automated cleaning and disinfection of instruments. In contrast to manual reprocessing, which can be time-consuming and laborious, the device saves valuable working time. The practice team can therefore concentrate more on treating the animals.

2. standardized processes

By using a thermal disinfector, instruments are always reprocessed according to the same programs and under consistent conditions. This ensures consistently high quality, regardless of different operators or other influencing factors.

3. safety of the practice team

The protection of staff is the top priority. As the washer-disinfector minimizes direct contact with contaminated instruments, the risk of puncture injuries, which often occur during manual cleaning, is significantly reduced.

4. preserving the value of the instruments

Gentle cleaning without aggressive disinfectants helps to keep instruments in good condition for longer. This leads to cost savings, as fewer replacements are necessary.

5. cost savings

Although the purchase of a washer-disinfector is an investment, there are considerable savings in the long term. With a washer disinfector, instruments can be cleaned and disinfected efficiently and cost-effectively. The low cycle costs for electricity, water and process media are around € 2.00 for MELAG products. This means that the purchase of a washer-disinfector pays for itself after around 25 months compared to manual cleaning and disinfection, which is more labor-intensive.